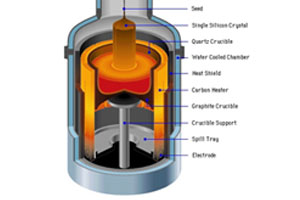

Solar cells are made from silicon boules, polycrystalline structures that have the

atomic structure of a single crystal. The most commonly used process for creating

the boule is called the Czochralski method. In this process, a seed crystal

of silicon is dipped into melted polycrystalline silicon. As the seed crystal is

withdrawn and rotated, a cylindrical ingot or "boule" of silicon is formed. The

ingot withdrawn is unusually pure, because impurities tend to remain in the liquid.

Making silicon wafers :

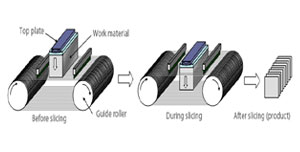

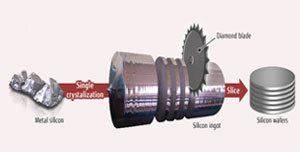

- From the boule, silicon wafers are sliced one at a time using a circular saw whose

inner diameter cuts into the rod, or many at once with a multiwire saw. (A diamond

saw produces cuts that are as wide as the wafer—. 5 millimetre thick.) Only about

one- half of the silicon is lost from the boule to the finished circular wafer—more

if the wafer is then cut to be rectangular or hexagonal. Rectangular or hexagonal

wafers are sometimes used in solar cells because they can be fitted together perfectly,

thereby utilizing all available space on the front surface of the solar cell.

- The wafers are then polished to remove saw marks. (It has recently been found that

rougher cells absorb light more effectively, therefore some manufacturers have chosen

not to polish the wafer.)